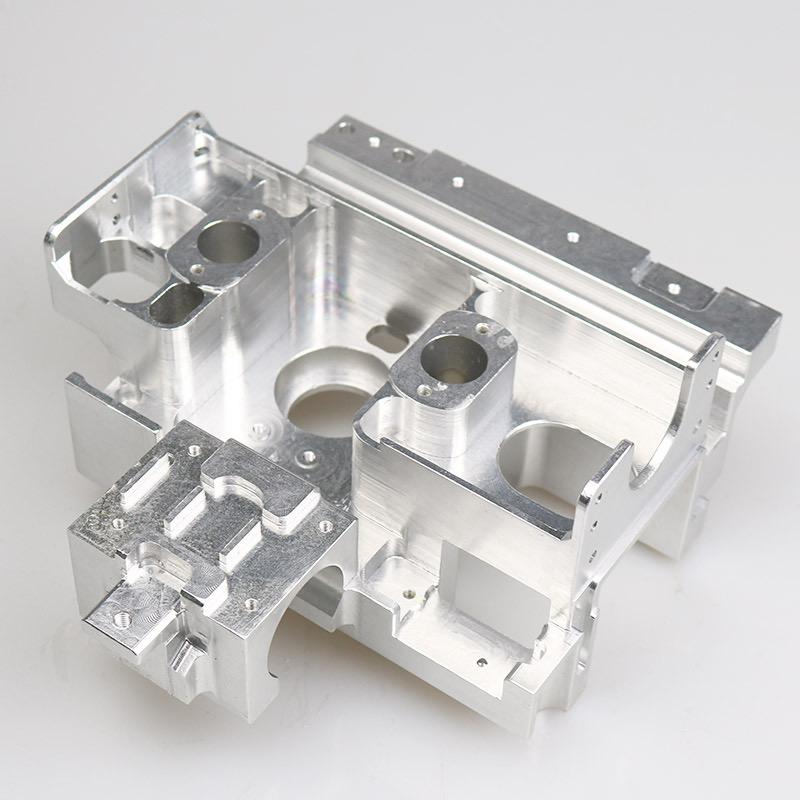

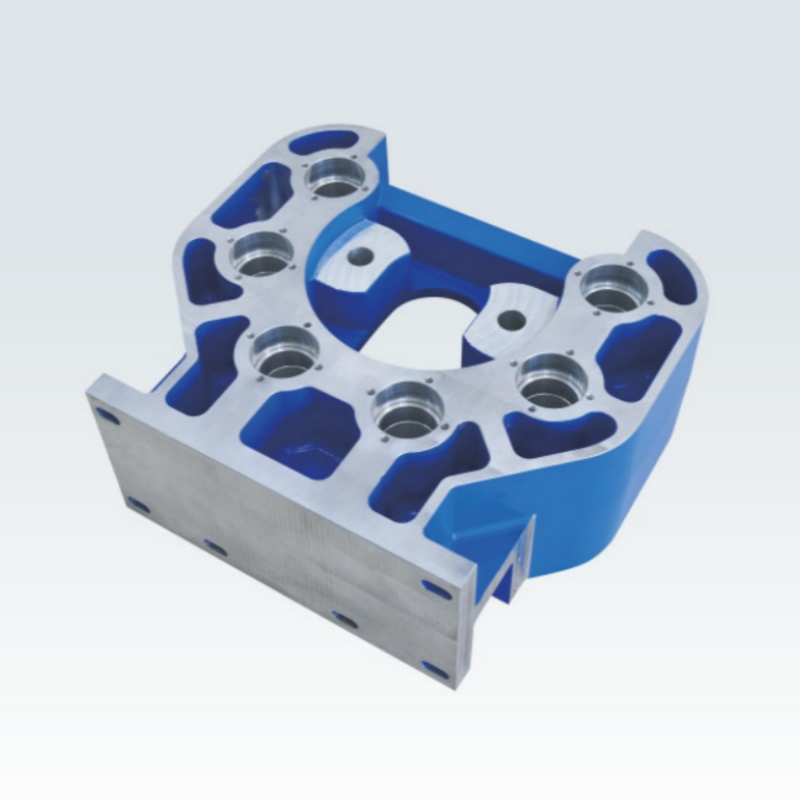

Le-creator CNC Machining utilizes advanced 3-axis, 4-axis, and 5-axis CNC equipment to provide a wide range of over 60 machined metals and plastics. Our comprehensive CNC machining services encompass CNC milling, CNC turning, EDM, wire EDM, surface grinding, and more.

What makes us deserving of your attention?

When you contact us, you will discover that our value exceeds your imagination. We received thousands of drawings for processing and have established our own database to efficiently develop the most cost-effective manufacturing processes for various shapes and material requirements. By accurately understanding the loss and allowing a margin, we ensure that the products we manufacturer strictly adhere to tolerance requirement on the drawings. Additionally, we consider factors such as rebound force, stress release ,and other variables resulting from different material properties and manufacturing processes in diverse environments.

| CNC 3&5 axis Miling | ||

| Size | Metric units | Imperial units |

| Max Part Size(LWH) | 1300*700*650mm | 51.2*27.6*25.6 in |

| Min Feature Size | Ø0.50 mm | Ø0.019 in |

| CNC Turning | ||

| Size | Metric units | Imperial units |

| Max Part Size(LxD) | 1200* Ø630mm | 47.2* Ø 24.8 in |

| Min Feature Size | Ø0.50 mm | Ø0.019 in |

| Industrial Tools | Aviation | Telecommunication |

| Dimensional Accuracy :0 .01 mm | Dimensional Accuracy : 0 .008 mm | Dimensional Accuracy :0.01mm |

| Surface Flatness :0 .03mm | Surface Flatness : 0 .008 mm | Surface Flatness :0.05mm |

| Parallelism :0 .03mm | Parallelism :0 .02 mm | Positional Accuracy :0.01mm |

| Positional Accuracy :0 .01 mm | Positional Accuracy :0 .01 mm | |

| Roughness :Ra 0 .4 | ||

| Medical Instrument | Fixtures, & Others | Semiconductor |

| Dimensional Accuracy :0 .01 mm | Dimensional Accuracy :0 .01 mm | Dimensional Accuracy :0.01mm |

| Surface Flatness :0 .02 mm | Surface Flatness :0 .005 mm | Surface Flatness :0.005mm |

| Parallelism :0 .02 mm | Parallelism :0 .01 mm | Parallelism :0.01mm |

| Roughness :Ra 0 .4 | Roughness :Ra 0 .4 | Roughness :Ra0.4 |

What is CNC Machining?

There are many types of CNC machines. They all use a computer controlled machine tool to remove material from the workpiece.. Because of this computer control, CNC machining is much faster, more precise and accurate than conventional machining.

What is CNC Machining used for?

Our precision CNC machining services make complex finished parts and components as well as tools for plastic injection molding or pressure die casting. In addition, CNC manufacturing is used for secondary drilling, tapping, and milling operations on machined parts or parts made from other processes.

CNC machine tools come in many specialized types to perform all kinds of operations on raw stock. However, CNC mills are the most common and versatile multi-axis machines that we use at Le Creator every day.

Referring to our previous previous CNC machining orders, over 90% of them are finished in around 7 days. Simple CNC machined parts can be done within 2 days, while it might take 15+ days to make complex or big CNC machined parts. Quantity is another matter to be considered. From our CNC machining manufacturing networks, we can also machine your parts from our CNC machining shops which is close to your location in the US and Europe which shorter the shipping time.

First of all, make sure the parts are designed friendly for CNC machining process. For example, avoid the features like sharp corners, deep pocket and thin walk. Secondly, select the right CNC machining companies for your projects. For the simple CNC machined parts, you can easily find the small CNC machine shops to get parts done at a better price. If you need precise CNC machined parts with complex geometries, then a CNC machining company like 3ERP who have 5-axis CNC machines and inspection m

Le-creator is known as one of the best CNC machining companies in China in terms of quality, speed, and customer service. With high-quality CNC machines, we can easily achieve +/- 0.02mm of tolerance and can even get within +/- 0.01mm. But keep in mind that it can have an impact on the cost.

Le-creator owns two CNC machining shops with over 60 sets of CNC milling and CNC turning machines. And we have more than 40 experienced technical experts, therefore we can guarantee to manufacture 5000 pcs different types of CNC machined parts in-house. Besides that, thanks to our verified manufacturing partners from our manufacturing network, we can offer extra CNC machined parts unlimitedly.

Yes. As soon as we receive your RFQ, our engineers will review the CAD files and offer the design optimization suggestion for CNC machining if needed. In order to get better CNC machined parts quality and sort out the points which affect the unit price.