Our 3D printing services are well-suited for the rapid prototyping and production of intricate functional parts. Our state-of-the-art 3D printing facilities are staffed by experienced operators and equipped with cutting-edge additive manufacturing technologies, encompassing four high-quality printing processes: Selective Laser Sintering, Stereolithography, HP Multi Jet Fusion, and Selective Laser Melting. With Le-creator, you can expect prompt delivery of meticulously crafted and precise 3D printed prototypes and end-use parts that cater to both low-volume and large-scale production requirements.

| SLA | MJF | SLS | FDM | SLM | |

| Lead Tine | 3 Days | 3 Days | 3 Days | 3 Days | 5 Days |

| Build Volume | Maximum 736X 635x 533mm | The maximum size is 356x 280x 356mm | The maximum size is 320x 320x 580mm | Max 914x 610X 914mm | Maximum 100x 100x 150mm |

| Layer thickness | Minimum 0.02 mm | Minimum 0.08 mm | About 0.1 mm; for impervious parts, 1.5 mm for higher wall thickness | About 0.05-0.3 mm | About 0.1 mm |

| Minimum feature size | 0.1 mm | 0.7 mm | 0.75 mm | 0.2 mm | A minimum of 1 mm is recommended |

| Tolerance | ± 0.2 mm | ± 0.2 mm | ± 0.3 mm | ± 0.3 mm | (± 0.1 mm) . However, the first attempt in a new design does not guarantee tolerances |

| Description | Rapid machining high precision, high surface quality, multi-detail hand sample, for appearance verification, assembly check, etc. . | Used for processing nylon parts appearance, assembly, prototype, support parts, small batch parts production, etc. . | Applicable to the production of functional hand plate, terminal parts of the production, and direct or indirect for a variety of fast casting | Rapid machining hand sample, can be used for appearance verification, assembly verification, etc. | For processing standard metal appearance, assembly, prototype, support parts, small batch parts production, injection mold, etc. |

| High precision, high speed, low price | High precision, no need for post-processing | The molding material is extensive, does not need the post-processing | Fast and cheap | High strength and precision | |

| Applicable | Photosensitive resin | Gray, colored nylon | Metals, ceramics, nylon, etc. | PLA, ABS, etc. | Metal |

What’s 3D Printing?

3D printing is a technology based on digital model files, which uses metal powder or plastic and other adhesive materials to construct objects layer by layer. It is also a new modeling technology involving CAD, CAM technology, data processing technology, material technology, CNC technology, test sensing technology and computer software technology.

Why Choose Le-Creator for 3D Printing?

Reduce your cost

Although 3D printers require power to operate, there is generally no material wastage involved. Subtractive processes like machining, on the other hand, produce waste material. Since 3D printing uses only the required material and needs no tooling, it is one of the most affordable manufacturing processes for one-off parts or small batches.The speed and versatility of 3D Printing lets product developers create physical snapshots of their designs through the iterative process.

Wide Materials Selection

Across our three 3D printing technologies, we use a range of commercial-grade thermoset resins, and thermoplastic and metal powders to 3D print parts that are suitable for various part applications and industries. If required for your parts, we offer a variety of post process options such as heat treating, secondary machining, plating, painting, and dyeing to further enhance mechanical properties and cosmetics.

Consultative Quotation

Get design feedback from our Le-Creator experienced and professional engineering team that has helped thousands of customers bring their products to market with high quality 3D-printed parts. We will also work with you to determine optimal parts orientation based on your application’s needs.

Flexible production

Le-Creator has 3D printing machines that produce metal and plastic parts of your projects wheather it’s a small batch and mass production. Once a part has been designed using CAD software, it can be printed in a matter of hours, without a lengthy setup procedure for your rapid prototypes. 3D Printing can be used to create fully-functional prototypes, complete with moving parts, as well as all-in-one assemblies.Because of the feature of 3D printed parts require no tooling, there is less risk involved when producing a part. If a flaw is discovered after printing, it can be amended digitally without replacing expensive tooling.

Precise and Professional

Our leading industry tolerances and surface finish quality stems from a dedicated process engineering and quality team for each 3D printing or addictive manufacturing technology. The high precision and conformity of 3D printing makes it an ideal way to build production quantities of separate or customized parts.

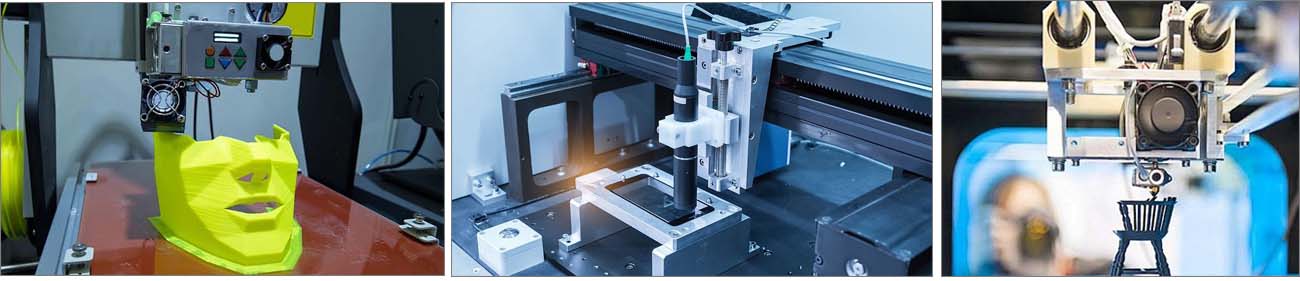

A section of the product display

Get your prototyping and production projects started today